| Abu | Ƙirƙira | Yin wasan kwaikwayo |

| Tsari | Yin ƙirƙira wani tsari ne wanda yin amfani da injin ƙirƙira don sanya ƙarancin ƙarfe ya haifar da nakasar filastik, don samun takamaiman kaddarorin inji, siffa da girma. Ta hanyar ƙirƙira na iya kawar da ƙarancin lahani na ascast na ƙarfe a cikin tsarin narkewa, haɓaka microstructure, ci gaba da kwararar ƙarfe cikakke, don haka kayan aikin ƙirƙira gabaɗaya sun fi simintin kayan aiki iri ɗaya. Yawancin na'ura masu mahimmanci sassan whcih suna buƙatar babban nauyi da yanayin aiki mai tsanani suna amfani da sassa na ƙirƙira. | Yin simintin gyare-gyare tsari ne da ke sanya ƙarfen ruwa a cikin rami na simintin, bayan sanyaya da ƙarfi don samun sassan da ake buƙata. |

| Kayan abu | Forging abu yadu amfani zagaye karfe, square karfe. akwai carbon karfe, gami karfe, bakin karfe da kuma wasu marasa taferrous karfe wanda yafi amfani a areaospace da daidaici masana'antu. | Yin simintin gyare-gyare yakan ɗauki baƙin ƙarfe launin toka, baƙin ƙarfe na simintin ƙarfe, baƙin ƙarfe mai yuwuwa, da "ƙarfe simintin gyare-gyare. Ƙarfe na yau da kullun wanda ba na ƙarfe ba: tagulla, tagulla, wuxi tagulla, gami da aluminum da sauransu. | Ƙarƙashin daidaitaccen yanayin, ƙarfe mai ƙirƙira yana da kyakkyawan aiki a cikin kayan aikin injiniya, yayin da simintin gyare-gyare ya fi gyare-gyare. |

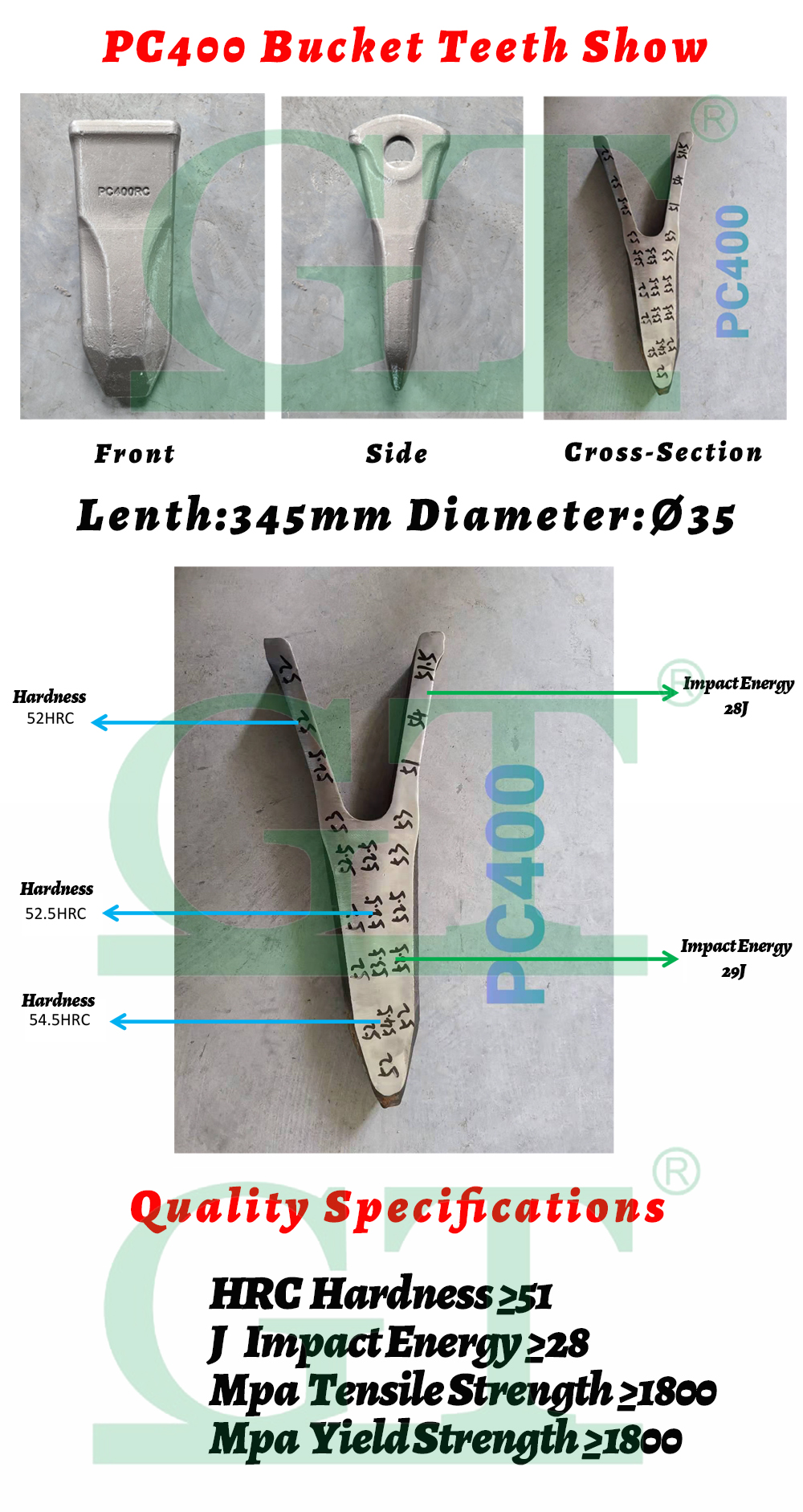

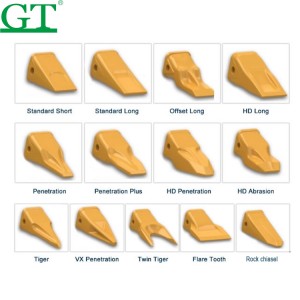

| Fuskanci | Halin iskar oxygen na ƙirƙira ƙarfe yayin aikin zafin jiki mai zafi zai haifar da ɗan ƙaramin ƙwayar kylin a saman jabun haƙoran guga. Hakanan kamar yadda ake yin ƙirƙira ta hanyar yin gyare-gyare, bayan cire ramin izini a cikin ƙirar, za a sami layin rabuwa a cikin jabun haƙoran guga. | Akwai alamar yashi da simintin gyare-gyare a saman haƙoran simintin guga. |

| Kayan Injiniya | Tsarin ƙirƙira na iya ba da tabbacin ci gaban fiber ɗin ƙarfe, kuma ya ci gaba da kwararar ƙarfe cikakke, tabbatar da kyawawan kaddarorin injina da tsawon rayuwar haƙoran guga, wanda tsarin simintin ba ya misaltuwa. | Idan aka kwatanta da sassa na simintin gyare-gyare, ana iya inganta tsarin ƙarfe da kaddarorin inji bayan ƙirƙira. The simintin kungiyar bayan ƙirƙira thermal nakasawa, asali girma crystal da columnar hatsi canza zuwa lafiya hatsi, da kuma uniform isometric recystallization kungiyar, bari tsarin na asali segregation ciki ingot, osteoporosis, porosity slag hada da sauran m zama mafi kusa, don haka inganta karfe plasticity da inji Properties.

Ƙirƙira shine samun siffar da ake buƙata ta danna ƙarfe ta hanyar nakasar filastik, yawanci ta hanyar guduma ko matsa lamba. Tsarin ƙirƙira yana ba da tsari mai kyau na granular, kuma yana haɓaka kaddarorin ƙarfe na zahiri, a cikin amfani mai amfani, ƙirar da ta dace na iya ba da tabbacin kwararar hatsi a cikin hanyar babban damuwa. Yayin da ake yin simintin gyare-gyaren don samun ƙarfe na ƙarfe ta kowane nau'i na hanyar simintin, wato sanya ƙarfen ruwa a cikin shirye-shiryen da aka shirya don samun takamaiman tsari, girma da kaddarorin, ta hanyar narkewa, simintin, allura ko wata hanyar simintin, da girgiza bayan sanyaya, tsaftacewa da magani na ƙarshe. |